Deposy on the Way to the Test System

By avoiding plastic waste and increasing recycling, considerable advantages in resource and climate protection can be realized.

Therefore Deposy, the innovative deposit system based on IOTA, wants to improve the basic conditions for increased recycling.

In Germany alone, a nationwide expansion of Deposy could save over 1 million tons of CO2 compared to waste incineration. This will be achieved by providing an incentive to collect plastic waste and sort it according to type. Deposy is fully on schedule with regard to technical implementation of the roadmap, which envisions a first prototype by the end of 2020. In addition, the course is currently being set for national and international cooperations, which should enable implementation on an industrial scale.

The global recycling rate for plastic packaging is only 14 percent.

40 percent ends up in landfills and 14 percent in incinerators. The remaining 32 percent go into the environment, seas and other bodies of water. In Germany, well over 50% of plastic waste is incinerated, much more than is recycled. The reason is that it is cheaper to produce new plastic than to use recycled plastic. With last year’s waste law, politicians are trying to counteract this and prescribe binding, increasing recycling quotas. This poses a major challenge to the industry.

Basically, the most sensible thing to do is not to let plastic waste arise in the first place. For example, by doing without plastic packaging either completely or to a large extent. This is currently an illusion from a global perspective, so Deposy, as an innovative deposit system, offers a win-win situation for manufacturers, recyclers, dealers and customers. Through an innovative deposit system as well as incentives for collection for the population, the system creates purely sorted plastic waste, which enables sensible recycling. With recycled plastic, 2.5 – 4 t less CO2 emissions are produced per tonne of plastic compared to a waste incineration plant. With a plastic waste volume of 0.52 million t per year (in Germany), which is estimated to be accessible for the Deposy deposit system, the system could, according to own calculations, contribute to saving 1.3 – 2 million t of CO2.

Deposy presented a tight roadmap in December last year, which envisages the realisation of the system up to a first prototype by 2020. The team has accepted the challenge it set itself and has made great progress in recent weeks. On the one hand, the team is focusing on technical details that should not be underestimated, and on the other hand, on future practical implementation on an industrial scale with partners both in Germany and globally. Currently, the Deposy System is completely on schedule with the roadmap.

In addition to the preparatory work for a possible future patenting of individual parts of the system, we reached the following milestones in recent weeks:

Wallet for the product ID

We have reported in detail about the unique Deposy Product ID in the blog articlehttps://www.deposy.org/en/path-to-deposy-product-id/. This contains the important properties of the product and is retained in any supply chain. To ensure this, each product ID is given its own wallet. This wallet and the QR Code addresses can now be generated automatically.

Transactions

The routine of generating transactions and sending IOTAs (What is IOTA?) to the wallet is now ready for use. In real operation, 1 IOTA is sent to the wallet to obtain the send address. This process is important to be able to verify afterwards that the Product ID information was created and certified by Deposy.

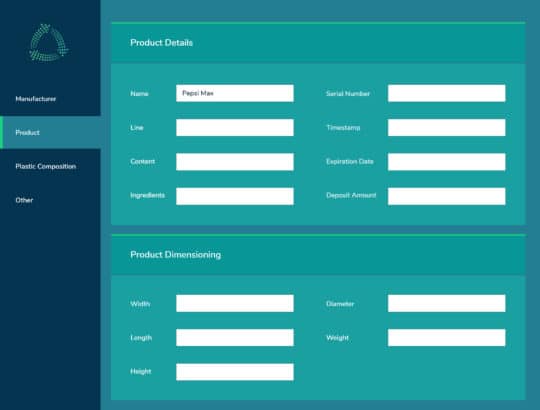

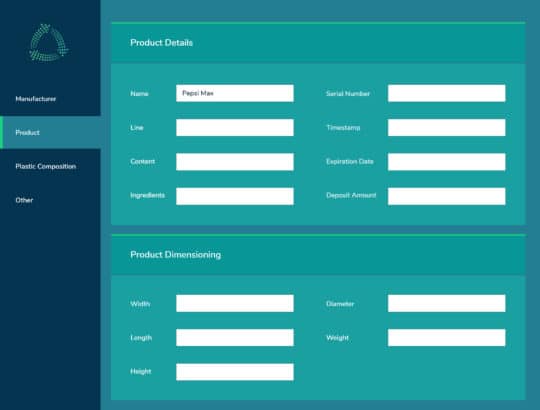

Software

In order to enable the digital integration of product batches of a plastic manufacturer via the Deposy system, a Deposy manufacturer software is created based on Python programming. This software enables a detailed and structured description of the product. The following characteristics are provided: Manufacturer details, product properties and plastic composition. For example, typical plastic compositions can be defined with the types polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC) and polyethylene terephthalate (PET), in order to ensure sorting by type and multi-component sorting. The data entered in the software is transmitted to the Deposy server as a JSON table.

Deposy App

We started with the development of an app, with which the system is operated by the customer. It serves as a communication interface between the consumer and the deposit system. The app will be a mobile wallet, via which, on the one hand, the deposit can be transferred to the user and, on the other hand, interfaces can be implemented, for example to Omoku, so that the user can receive the money in local currency. In the future, it can also serve as an output of the Product ID information.

Cooperations and testbeds

Nationally but also internationally there are many companies that deal with the plastic waste topic. In recent weeks there have been numerous enquiries from companies that are considering future cooperation with the Deposy System and are eagerly awaiting the first Deposy Test System. Currently, the conditions for future cooperation and collaboration are being created in a project-accompanying working group. Furthermore there are two offers for testbeds.

Further details on the individual points will be published in our blog.